By Jon Blaicher

The idea of moving to a larger boat is often driven by the associated benefits. More comfort and more room for more people, food and drink are often at the top of the list. It isn’t until the first sea trial that the realization you might have to dock a much larger boat than you are used to, finally sets in. An unfamiliar boat in an unfamiliar slip can be frightening, especially when it is significantly larger than the boat before it. I personally experienced such trepidation when moving from a 28-foot express cruiser to a 40-foot sedan bridge.

Like many a boater, I had bought into the folklore that a twin engine shaft-driven boat would be much easier to dock than my stern-driven express. Quite often I’d hear “You can dock with the throttles alone”, or “It’s easy, just don’t ever touch the wheel.” Huh?

My analytical left brain kept reminding me that the larger bridge yacht was 3-feet wider, weighed three times as much with at least double the windage compared to our previous express. Can a couple of shafts and rudders really circumvent Newton’s third law?

To hedge a little, I had the marina move us to an end slip, where we would only have to contend with one dock and no neighbouring boat. Luckily an end slip was available, and the longer walk was certainly worth the effort while I built confidence in docking the big sedan.

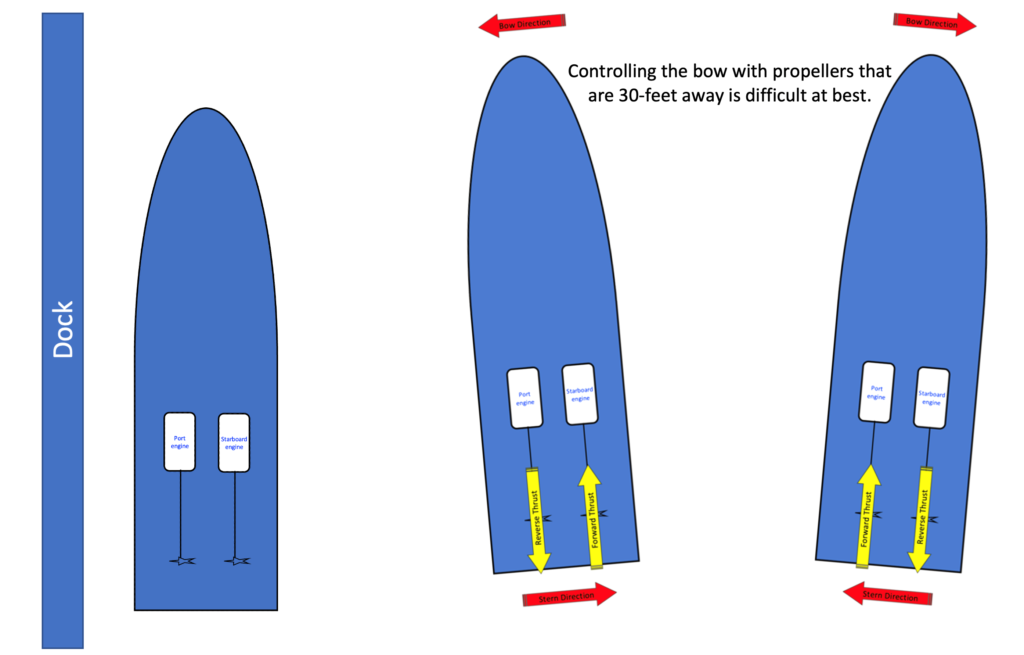

As it turned out, docking with shaft drives was a touch easier, but only if I stayed ahead of the wind and managed to get a bow or stern line on the dock cleat quickly. Larger diameter propellers located 3 feet inboard, combined with wider spacing on the hull meant fewer corrections and less throttle was required to turn or pivot the heavier boat. But… shaft propeller net forces are predominantly longitudinal – forward and aft only. While you can use the propellers to move the bow to port or starboard by putting one engine in forward gear and the other in reverse, the stern will inevitably be pushed in the opposite direction of the bow. Thank you, Sir Isaac! Nothing a few 28-inch fenders and a hundred hours of docking practice can’t fix. I’ve also heard momentum can be your friend and that is true, but only once. If the wind picks up, all bets are off.

Fortunately there is an affordable thruster solution that doesn’t require extra fenders, hands, poles, a frustrated spouse, or years of practice. One that completely removes the stress of docking!

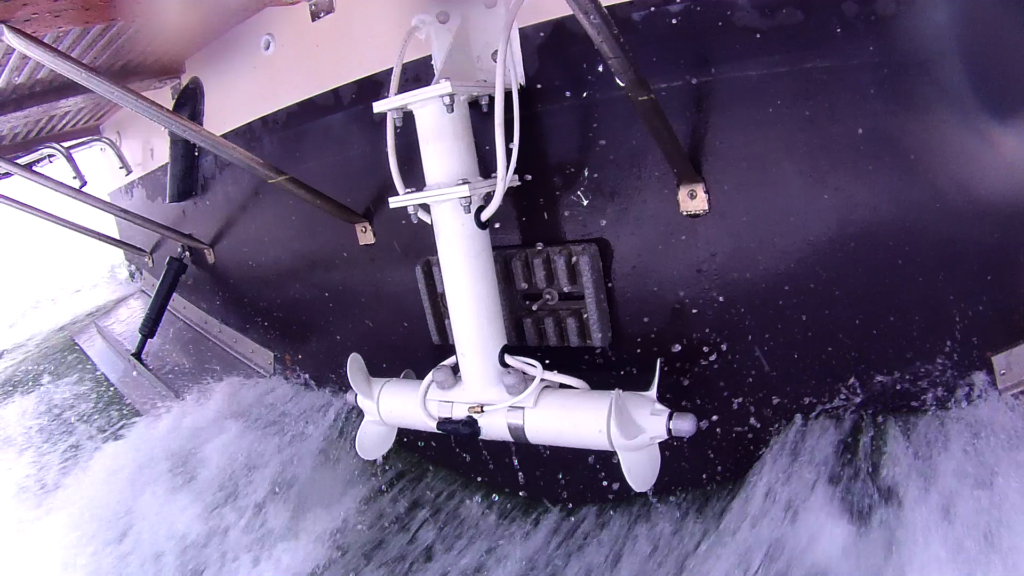

Sideshift’s innovative thruster systems do not require large tunnels be cut into the hull. The largest hole required through the hull is only a ½-inch or 13mm in diameter. No fibreglass work is needed and there are no holes below the waterline, eliminating the risk of leaks associated with other types of thruster systems. Since they are mounted above the planing surface, they do not contribute additional drag when on plane.

Sideshift thrusters can be installed by anyone with a knack for a DIY boat project and can often be completed in a single day. Each thruster is sold as a kit that includes every single part you’ll need except for batteries and cables. There is a detailed installation manual with dozens of photos and several installation videos available on the Sideshift website.

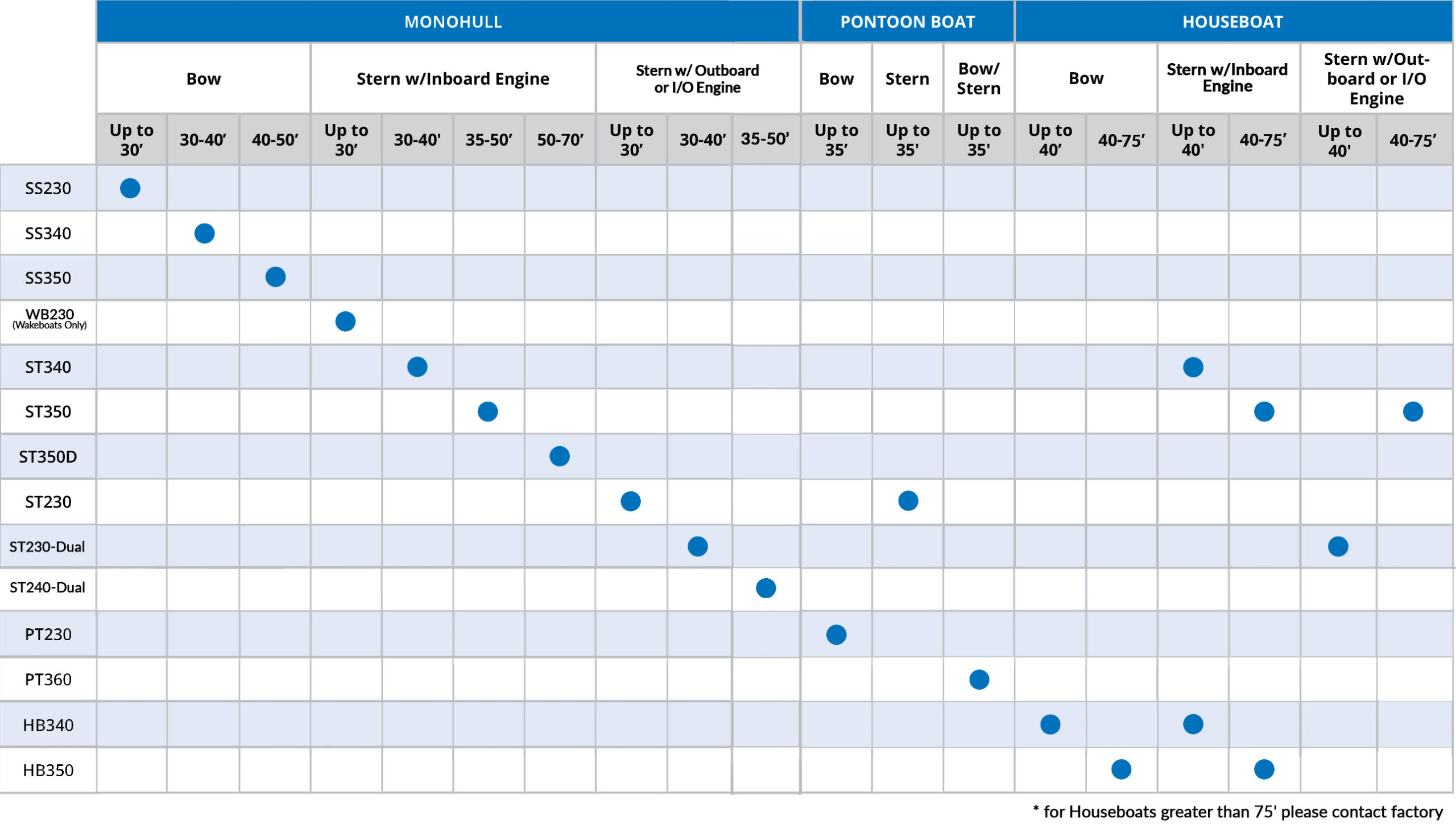

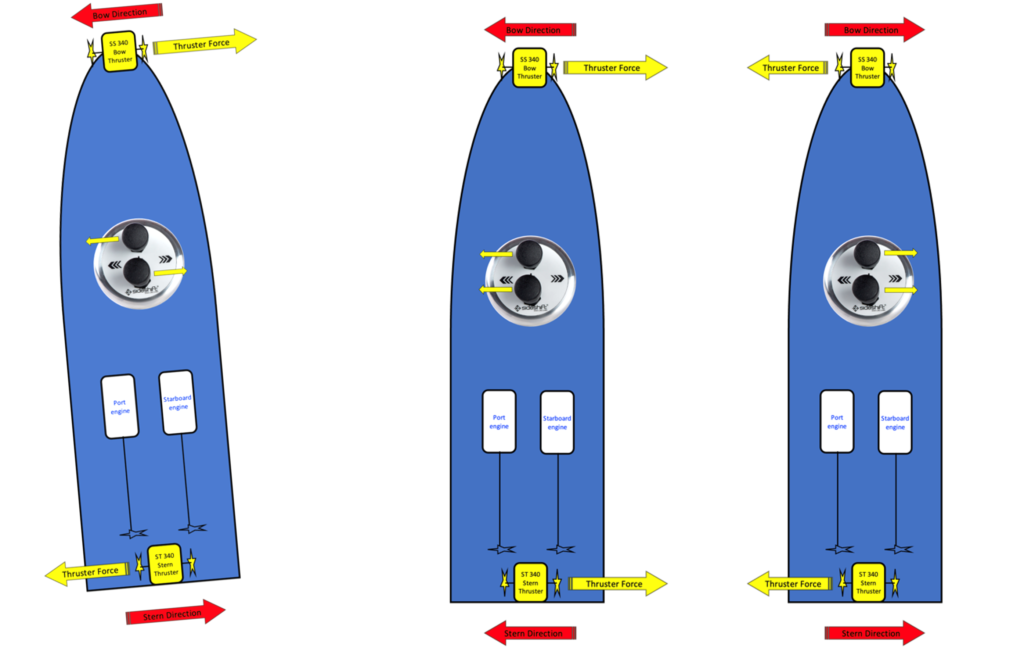

The 5.0 horsepower 12-volt SS340 bow, ST340 stern and ST340 OB thrusters are designed for boats from 30 to 45-feet in length and can often be connected to an existing 12-volt bank. Five horsepower may not seem like much, but thruster location at the very edges of the bow and stern provides thrust exactly where it is needed. Not only does this allow precise 360-degree control of the boat from the wireless joystick or remote lanyard, but it also means you can slide your boat completely sideways against an offshore breeze.

For even larger boats up to 60-feet in length, the SS350 bow, ST350 stern and ST350 OB thrusters punch the horsepower up to 7.5 with more powerful 24-volt motors.

All Sideshift thrusters are saltwater proven. Not only are they constructed of corrosion resistant aluminum and stainless with sacrificial anodes attached from the factory, but the exposed metal parts are covered with epoxy primer and then coated with anti-fouling paint!

To avoid one of those moments around the dock or a close call not worth repeating, check out our About Monohull Thrusters page. You might be surprised to find how affordable these stress relievers are!